A single unit that brings peace of mind and flexibility to the production site

The FA-9600 is a multipurpose processor that supports 4K, 12G, 6G, HDR, and WCG. It enables various types of processing on two streams of HD or SD video and audio signals in a single unit. With support for 12G-SDI, it also provides a range of features including sophisticated HDR conversion, SFP+ module support, and MADI, Dante, and analog audio input and output. It is a versatile solution for transmission centers, mobile production trucks, news stations, production studios, and other nonlinear editing and playout production environments.

Ready for the HDR and WCG era

Developed as an alternative to the 10-channel FA-1010 signal processor, this unit combines five channels with up/down/cross conversion. The ability to do so has proved to be a winning combination, especially where space is limited, such as mobile production. As capable as the FA-1010 in 4K signal processing, the FA-505 also responds to growing needs in other video parameters—HDR and WCG. Along with higher resolutions, these two technologies have the ability to reveal impressive beauty and realism. The FA-505 has pioneered HDR and WCG in signal processors. By supporting SDR/HDR and BT.709/BT.2020 conversion, the unit is a strong ally in next-gen video production.

Meeting current needs with more features and channels

In time, the appealing concept of the FA-9000 series—providing essential signal processing in an all-in-one solution—earned market respect, and the signal processors became standard industry equipment. But as the industry moved toward multi-channel production, more users called for multi-channel support in a single unit. The FA-9520 was released as a 2-channel version of the FA-9500 while FOR-A engineers worked on the FA-1010, which offers even more. This 1RU signal processing model features 10 interconnected processing circuits for its 10 inputs and 10 outputs. Separate color correction and audio processing is available for each channel, and I/O signals can be routed as needed, providing a versatile, all-in-one processing powerhouse. Unveiled at NAB 2013, the FA-1010 has made waves around the world.

Advent of an all-in-one signal processor

As the shift to HD at broadcast studios drove demand for HD equipment, FOR-A engineers thought outside the box in new FS/TBC development and supplemented HD support with up/down/cross conversion to offer an all-in-one signal processor. But with so many features, the simple front panel of previous units wasn’t going to provide enough control. Inspiration struck when an engineer happened to see a photo of a navigation system with illuminated buttons that could be used even in the dark, which led to the backlit, color-coded buttons on the FA-9000. This innovative unit started a new chapter in FOR-A signal processors that has continued through the FA-9100, FA-9500, FA-9520, and FA-1010.

Offering standalone and modular options

This model introduced a compact, economical TBC applying FA-350 series digital technologies. Several versions were developed after the FA-115 (supporting analog composite I/O), including the FA-125 (Y/C I/O), FA-145 and FA-147 (SD-SDI), and 14-bit FA-128. Users also had a choice of modular versions. System builders could simply choose the required module to be added to a universal frame.

Entering the digital era of the 21st century

At the dawn of the 21st century, FOR-A celebrated its 30th anniversary. For notable turn-of-the-century FA products, new digital technologies were introduced, with younger engineers leading development. Associated with this first series (FA-350, supporting analog composite video) were the FA-360 (analog component), FA-370 (SD-SDI), FA-390 (SD-SDI+audio I/O), and the FA-395 (expanded audio) and successor FA-395A. Even a decade after launch, they remain leading products.

FA-310 series: Truly out-of-this world performance

When major Japanese broadcaster TBS planned to record a spaceflight to Mir, FOR-A received a special order for equipment to prepare the footage for viewers back on Earth. Requirements were strict: Not only would the launch subject equipment to intense vibration, TBS was paying a lot for cargo—by the gram. In August 1990, FOR-A presented a customized FA-310P (and a spare) in an aluminum enclosure. Stripped down to essentials, silicone adhesive was used for mounting. On the mission, the special-order FA-310P performed well, and TBS representatives later visited FOR-A to express their thanks in person. The commercialized product also performed well in the market, breaking FA series sales records at more than 13,000 units.

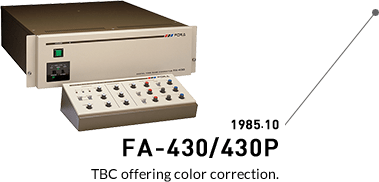

An era of acclaimed FOR-A TBCs

In 1985 Sakura R&D Center opened its doors in Chiba Prefecture, developing products focused on the frame synchronization of TBCs. Time-based correction was only one role of TBCs, which evolved to offer frame synchronization, clip memory, signal processing, and transcoding. In fact, feedback revealed that TBCs were being used in surprising ways, and that users had many unexpected needs. Meeting these needs around the world was difficult, especially because VTRs and VCRs varied by manufacturer, but this work distinguished FOR-A as a leader in TBCs—to the extent that sales representatives at trade shows were sometimes surprised with orders for hundreds of units.

First model in the FA series.

Under the guidance of an American engineer, FOR-A set out to develop an original time base corrector (TBC) for worldwide release. This is the origin of FA in signal processor model names since then—F from FOR-A and A from the engineer's name. In fact, the engineer hosted FOR-A representatives at his home when development began. Although their prototype was ready to unveil at IBC in 1981, unresolved cooling issues forced them to turn the unit off between booth visitors. Once temperature characteristics were improved, the final product was ready. In all, sales volume topped 1,500 units.